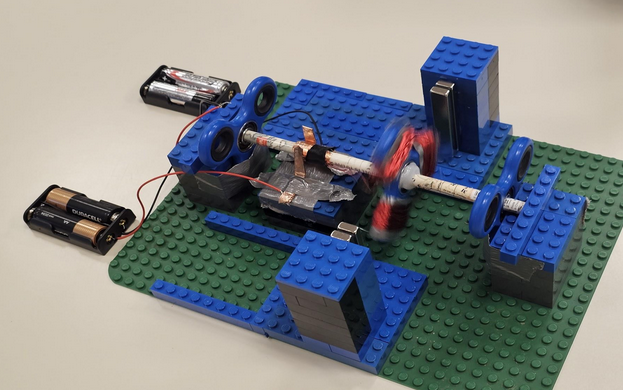

A still of the fidget spinner rotor in motion

The Project

One of the major deliverables for ENGR 320 – Electromechanical Devices was to work in a group of 5 and create a functional motor. The design parameters for the project were rather loose, so the group decided to adopt a unique design: fidget spinners!

A GIF of starting the motor

More specifically, the parameters our group focused on for our design was cost, ease of modification and troubleshooting during development, and, of course, uniqueness. By placing the coils on the fidget spinner’s “legs” and exploiting the low friction of the fidget spinner’s bearings, we were able to successfully create a brushed copper-based 3-coil 6V DC double pole motor that was able to rotate for over 30 seconds continuously.

Additionally, by using Lego, the group was able to easily alter the geometry of the setup as the product design evolved.

Close-ups of the brushes and commutator

Ultimately, while the motor performed well and passed the project requirement of over 8 seconds of uninterrupted motion, several areas of improvement include adding a controlled stop-start mechanism to the motor (as opposed to the manual method as seen in the GIF above), increasing the motor performance through various means such as additional poles and stronger magnets, and using more robust materials beyond Lego and duct tape, though such material selection did keep the cost of the project down to a minimum.